Abrasive & Diamond Tools

Home / Abrasive & Diamond Tools

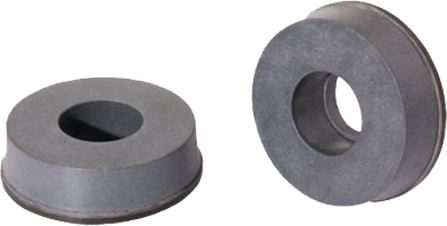

SIC ABRASIVE L140MM

Used in all kind of polishing machine, especially for polished tiles, marble and granite, with the feature of good sharpness. Long working life, high output, low integrated cost uniform polished resull and high gloss.

Specification

| Name | Type | Grit | Average Weight | |

|---|---|---|---|---|

| SIC ABRASIVE | 140MM | Rough | 36#, 46#, 60#, 80#, 100# | 1.1 |

| 170MM | ||||

| Medium | 120#, 150#, 180#, 220#, 240#, 280#, 320# | 1.1 | ||

| Fine | 400#, 600#, 800#, 1000#, 1200#, 1500#, 1800# | 1.1 | ||

DIAMOND FICKERT

Diamond Abrasive is mainly used in continuous production line for rough and smooth grinding of ceramic tiles instead of SiC abrasives. Characteristics: Strong cutting, high capacity,stable performance, long working life, low cost and environment-protection etc.

Specification

| Name | Type | Granualarity | Average Weight |

|---|---|---|---|

| DIAMOND FICKERT | 140MM(T1) | 36#, 46#, 60#, 80#, 100#, 120#, 150#, 180#, 220#, 240#, 280#, 320#, 400# | 1.1 |

| 170MM(T2) |

LAPATO ABRASIVE STONE

Glaze polishing abrasives are used on normal polishing machines ho make flexible full polishing on the surface of rustic tiles, stone like porcelain tiles and glaze tiles, Our glaze polishing abrasives are approved for their excellent shaping effect. Good sharpness, high gloss and long service life.

Specification

| Name | Type | Granualarity | Average Weight |

|---|---|---|---|

| Glaze Polishing Abrasives Tools | 140MM(T1) | 80#, 100#, 120#, 150#, 180#, 220#, 320#, 400#, 500#, 600#, 800#, 1000#, 2000#, 3000#, 5000#, 6000#, 8000# | |

| 170MM(T2) |

DIAMOND ROLLER

Diamond Roller is one of the most frequently used abrasive tools for processing ceramic tiles, mainly used for calibrating the tile and adjusting its thickness before polishing. Our company, by using of the latest abrasive formula and the most advanced technology is able to produce high quality diamond rollers that featured with high sharpness, low noise and stable quality as well as, being endurable.

Specification

| Name | Length | Segment Length | From | ID | Segment Size | Spiral | Grit |

|---|---|---|---|---|---|---|---|

| DIAMOND ROLLER | 300 400 500 600/630 800/830 1000 |

295 395 495 595/600 795/800 995 |

F215 / 216 / 236 / 240 | 70 76 80 90 |

9*13 | 5/7 | 30#, 40#, 50#, 60#, 70#, 80#, 90#, 100#, 110#, 120# |

DIAMOND SQUARING WHEELS

used for the uprightness of four edges of ceramic and glazed tiles to obtain the desired size. We can adjust the making formula and segment size to reach the best working efficiency upon customer's request. It's advantage are :Good Sharpness, durable, lower noise and smooth surface

Specification

| Od | Id | Segment Size | Grit | |

|---|---|---|---|---|

| 150 | 80/110/140 | W | H | 40# ~ 120# |

| 200 | 8x12 9x13 10x12 10x14 | |||

| 250 | ||||

| 300 | ||||

RESIN DRY SQUARING WHEELS

Specially used in dry squaring machine, with the feature of long working life, good sharpness, good heat dispelling, low dust and noise.

Specification

| Od | Id | Segment Size | Grit | |

|---|---|---|---|---|

| 200 | 50/80/140 | W | H | 140# ~ 240# |

| 250 | 25 | 12 | ||

DIAMOND DRY SQUARING WHEELS

Specially used in dry squaring machine, with the feature of long working life, good sharpness, good heat dispelling, low dust and noise.

Specification

| Od | Id | Segment Size | Grit | |

|---|---|---|---|---|

| 200 | 50/80/140 | W | H | 140# ~ 240# |

| 250 | 25 | 12 | ||

RESIN CAMBERING WHEEL

(For Tiles Chamfering)

Specially used in dry squaring machine, with the feature of long working life, good sharpness, good heat dispelling, low dust and noise.

Specification

| Od | Id | Segment Size | Grit | |

|---|---|---|---|---|

| 130 | 50/80/140 | W | H | 140# ~ 170# |

| 150 | 25 | 12 | ||

ALUMINA PEBBLES & ALUMINA BRICKS

Being the wearing liner for the ball mill, alumina lining brick is the best choice to increase the grinding efficiency and reduce the grinding cost. CurrenHly, alumina lining brick is being widely used in ceramic, cement, paint,pigment,chemical,pharmacy and coatings industries.

Specification

| Alumina Balls | Diameter | Alumina % |

|---|---|---|

| 10,12,15,18,30,40,50,60 | 68%, 75%, 92% |

CERAMIC ROLLER

Applying the most advanced pressing technique high density; Low thermal expansion coefficient, the highest working temperature is up to 1350℃ ;High loading in working temperature, most suitable for the kilns of wide-body,high speed and heavy loading.

Specification

| Diameter (mm) | Length (mm) | Diameter (mm) | Length (mm) |

|---|---|---|---|

| 65-80 | 3000-5000 | 40 | 2000-3500 |

| 60 | 2700-5000 | 36 | 2000-3300 |

| 55 | 2700-5000 | 35 | 2000-3200 |

| 50 | 2400-4600 | 33.7 | 1800-3100 |

| 45 | 2200-3800 | 32 | 1800-3100 |

| 42 | 2200-3800 | 20-31 | 1600-3100 |

SILICON CARBIDE BURNER TUBE

Burner Tubes have superior rapid cooling and rapid heating resistance, wear resistance, oxidation resistance, high bending strength,no falling slag. no crazing, have a long time service life, easy to change, effective to control the uniform temperature inside the kilns.