Kaolin Clay

Home / Kaolin Clay

Kaolin Clay

Unlock the potential of our premium Kaolin Clay. Mined from select deposits and refined to perfection, our Kaolin Clay stands out for its exceptional purity and performance. Ideal for a wide range of applications including ceramics, coatings, polymers, cosmetics, and agriculture, it enhances product quality and aesthetics. This versatile ingredient is renowned for its gentle exfoliating and oil-absorbing properties, making it a go-to choice for formulators.

Elevate your formulations with Aqua Nano Chemical's superior Kaolin Clay, trusted for its quality and reliability across industries.

Types of Kaolin Clay

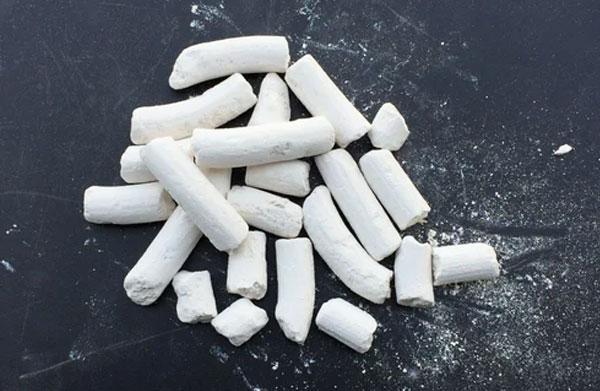

Explore our Kaolin Clay offerings available in three distinct forms including powder forms, levigated forms, and noodles forms to meet diverse application needs. Engineered for exceptional performance and consistency, our materials are trusted by ceramic manufacturers worldwide.

Powder Forms

Levigated Forms

Noodles Forms

Product Details

| PARAMETERS | Results | |||||||

|---|---|---|---|---|---|---|---|---|

| PI – 96(noodles) | PI – 96(M) | PI – 95(M) | PI – 95 | PI – 94 | PI – 92 | PI – 90 | 1RL | |

| Physical Composition | ||||||||

| Natural Appearance | Snow White | Snow White | Creamish | White | White | White | Creamish | Pinkish |

| Whiteness ( % ) | 87 ± 1 | 88 ± 1 | 84 ± 1 | 84 ± 1 | 83 ± 1 | 79 ± 1 | 75 ± 1 | 60 ± 1 |

| Residue on 325 # ( % ) | 0.5 Max | 0.5 Max | 0.5 Max | 0.5 Max | 1.0 Max | 1.0 Max | 2.0 Max | 2.0 Max |

| L – Value | 95 ± 0.5 | 96 ± 0.5 | 93 ± 0.5 | 94 ± 0.5 | 93 ± 0.5 | 92 ± 1.0 | 90 ± 1.0 | 83 ± 2.0 |

| A -Value | 0.52 | 0.1-0.3 | 0.97 | 0.84 | 0.84 | 1.61 | 1.39 | 3.31 |

| B – Value | 4.0 ± 0.5 | 3.0 ± 0.5 | 5.0 ± 0.5 | 4.0 ± 0.5 | 4.0 ± 0.5 | 4.0 ± 0.5 | 5.0 ±0.5 | 6.0 ±0.5 |

| Shrinkage | 5.5 ± 0.5 | 5.0 ± 0.5 | 6.0 ± 0.5 | 5.0 ± 0.5 | 5.5 ± 0.5 | 5.5 ± 0.5 | 7.0 ± 0.5 | 7.0 ± 0.5 |

| Temperature ( .C ) | 1220 | 1220 | 1220 | 1220 | 1220 | 1220 | 1220 | 1220 |

| Cycle ( Mins ) | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Water of Plasticity ( % ) | 36 ± 1 | 38 ± 1 | 38 ± 1 | 37 ± 1 | 36 ± 1 | 38 ± 1 | 38 ± 1 | 38 ± 1 |

| Water Absorption ( % ) | 15.56 | 19.98 | 14.3 | 14.2 | 15.42 | 19.24 | 17.09 | 15.81 |

| Dry MOR ( Kg / cm 2 ) | 6.3 | 9.7 | 6.8 | 6.4 | 5.6 | 8.8 | 9.1 | 12.2 |

| Fired MOR ( Kg / cm 3 ) | 37.6 | 46.2 | 40.8 | 38.8 | 39.3 | 45.6 | 58.2 | 88.2 |

| Chemical Composition | ||||||||

| Loss of Ignition ( % ) | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Sio₂ : ( % ) | 45 ± 1 | 48 ± 1 | 48 ± 1 | 46 ± 1 | 47 ± 1 | 45 ± 1 | 46 ± 1 | 51 ± 1 |

| Al2O3 ( % ) | 39 ± 1 | 36 ± 1 | 36 ± 1 | 37 ± 1 | 37 ± 1 | 37 ± 1 | 36 ± 1 | 32 ± 2 |

| Fe2O3 ( % ) | 0.2 -0.4 | 0.3 -0.5 | 0.3-0.5 | 0.3-0.5 | 0.3-0.6 | 0.4-0.7 | 0.5-1.2 | 2.0 Max |

| TiO₂ ( % ) | 0.5-0.9 | 0.8-1.2 | 0.9 -1.4 | 0.9 -1.2 | 0.9 -1.4 | 0.9 -1.4 | 0.9 -1.6 | 1.2-2.2 |

| K₂O ( % ) | 0.047 | 0.19 | 0.2 | 0.21 | 0.035 | 0.067 | 0.083 | 0.21 |

| Na₂0 ( % ) | 0.048 | 0.21 | 0.24 | 0.27 | 0.051 | 0.0396 | 0.1 | 0.14 |

| CaO ( % ) | Trace | 0.33 | 0.31 | 0.35 | 0.15 | Trace | Trace | Trace |

| MgO ( % ) | 0.097 | 0.3 | 0.32 | 0.31 | 0.107 | 0.109 | 0.17 | 0.29 |